The Parts Counter

The Uptime/Downtime Calculator

The Machine Cycle Timer

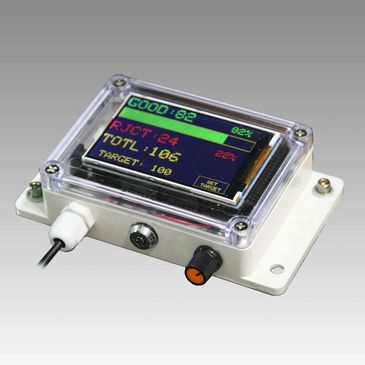

This device will count the repetition of an industrial process. Mostly intended for parts production tracking, it can handle two sensors, one for parts made and an optional one for rejects. A production goal can be set, and the green bar maps the progress.

This product is ideal for small parts production that are not easy to count by hand.

This device will count the repetition of an industrial process. Mostly intended for parts production tracking, it can handle two sensors, one for parts made and an optional one for rejects. A production goal can be set, and the green bar maps the progress.

This product is ideal for small parts production that are not easy to count by hand. It can be adapted to cutting machines, stamping, drilling and son on...

Our customers report increased accountability from their employees once this device is installed on a machine.

The Machine Cycle Timer

The Uptime/Downtime Calculator

The Machine Cycle Timer

This device will measure the time necessary for a machine to complete a manufacturing cycle. It is intended to alert the operator when the completion time is too slow, avoiding the loss of time. A five time average and a hundred time average are kept and updated with each cycle.

Practical example: An injection molding machine is supposed

This device will measure the time necessary for a machine to complete a manufacturing cycle. It is intended to alert the operator when the completion time is too slow, avoiding the loss of time. A five time average and a hundred time average are kept and updated with each cycle.

Practical example: An injection molding machine is supposed to produce one part per 10 seconds. If the time of production increases to 11.5 Sec, no one in the shop would know till the part count. This would result in a 15% loss of production. This Takt Time Lean"device will warn the operator early on.

The Uptime/Downtime Calculator

The Uptime/Downtime Calculator

The Uptime/Downtime Calculator

This Uptime Tracking Device will monitor your manufacturing downtime. By analyzing production uptime the user can minimize the equipment operational downtime. A machine uptime - downtime report is provided in real time on a TFT screen as a machine downtime log resulting in a reduction of the production downtime. The machine uptime can a

This Uptime Tracking Device will monitor your manufacturing downtime. By analyzing production uptime the user can minimize the equipment operational downtime. A machine uptime - downtime report is provided in real time on a TFT screen as a machine downtime log resulting in a reduction of the production downtime. The machine uptime can also be monitored providing the user with valuable usage data in real time. This can avoid overheating and high stress of a number of industrial equipment in need of a duty cycle calculator.

THE UPTIME DATA COLLECTOR™

All the above devices can be equipped with Radio communication. The data from multiple machines is reported in one place and logged in a CSV file every shift. Pricing Guidelines:

• 1 to 5 machines, $799 per machine, plus the receiver and PC.

• 6 - 10 machines $899 per machine. Includes receiver and PC.

Final pricing might vary based on your custom programming needs.

Machine Vision 3D Parts Quality Control: "The Sentinel"

Our company has developed a new low cost, fast speed quality control system. In this example the device is rejecting partially completed flower pots while keeping the good ones.

- One inspection per second while the parts are in motion.

- The system is inspecting a 3 dimensional part in real time.

- User friendly. An intuitive PC based interface allows operators to adjust the rejection threshold and other settings.

- Starting at $4999 the system is affordable to small manufacturing. Learn More

The Machine Cycle Timer with Data Collection

Our Cycle Timer™ can collect data for Excel

This solution was created by customer demand. Each machine cycle is being sent by USB cable to a PC where our Data Collector™ Software displays it and logs it in a CSV file. At midnight a new file is being generated.

This files allows management to see how productivity varied throughout the day and an optimize the production process.

Prices vary based on the data collected and number of machines. Please contact us with your needs.

Contact Us

Machine Cycle Timing, Downtime Tracking and Parts Counting

Mon | 09:00 am – 05:00 pm | |

Tue | 09:00 am – 05:00 pm | |

Wed | 09:00 am – 05:00 pm | |

Thu | 09:00 am – 05:00 pm | |

Fri | 09:00 am – 05:00 pm | |

Sat | Closed | |

Sun | Closed |

Copyright © 2023 Machine Cycle Timing, Downtime Tracking and Parts Counting - All Rights Reserved.

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.