The Uptime Calculator™

As soon as The Uptime Calculator™ is powered up, it starts logging time as "Elapsed". In the same time it is keeping a record of the "ON" time of your device and displays it as "UPTIME" and as a percentage of the elapsed time. The device also generates a two color bar, green indicating the uptime and red indicating the downtime. This can be used as a OEE (Overall Equipment Effectiveness) tracking device. See the real downtime tracking in the video. Now available with data collection

What Do You Get

The Uptime Calculator™

This device comes with instructions, 15 foot (5M) cable and and a 12V AC adapter. 1 year warranty, free shipping. Contact us to customize it to your needs if necessary. UPC 7426854516871

Success Stories from our customers

- This item has been installed on numerous assembly lines. Being able to know in real time how long the assembly line was running proved as a valuable productivity tool.

- The Uptime Calculator has been installed on an auger system that loads cereals in silos. In this situation the management wanted to know how much wheat is being moved up every day without having to weigh the stock.

- A laser engraving company has installed this on each engraving station. The Calculator provided the accumulated time of the laser being on during the shift. This became a metric for remunerating the employees. This could not have been done by counting the parts engraved since some jobs need different completion times than others.

- A welding company has installed this unit on various welding equipment. The welding was done on big tanks and it would have been difficult to measure the number of linear feet of weld each employee has performed per shift. By knowing the accumulated time the welding machine was on, the management could measure the welder's performance.

- This unit was installed on an automated cutting machine. When the blade was sharp the cutting time was typically 25% of the time. As the blade dulled the cutting time increased to about 50% resulting in decreased productivity. The unit became a reliable indicator of when to change the blade.

There are numerous industrial applications where this unit would pay for itself in a mother of months or even weeks.

Quick Start Your Uptime Calculator

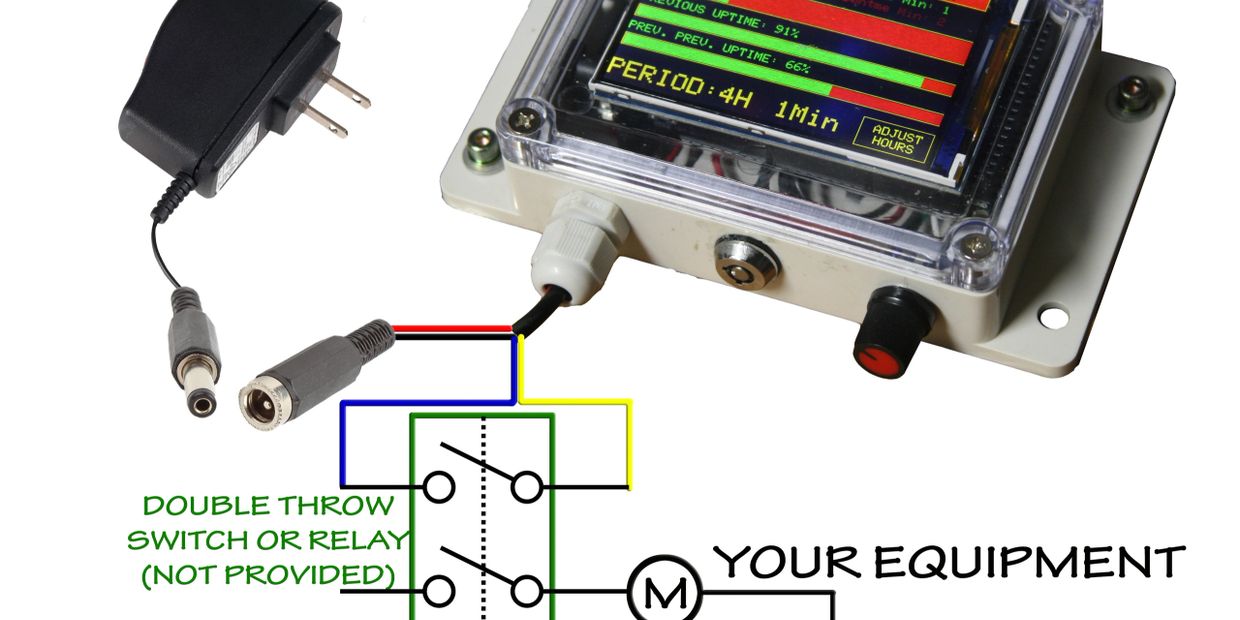

1. Make electrical connections as shown in the illustration above.

2. Observe the bottom right corner of the screen. If “Locked” please unlock it with the key.

3. Adjust the desired measurement period. Press knob briefly to flip between hours and minutes.

4. Press knob for 5 seconds to obtain a reset. This will delete the current cumulated uptime and move it to the “Previous Uptime” field.

5. Lock the Knob functions with the provided key. This will prevent operator interference (No Reboot) and electromagnetic interference from high power equipment.

In the event of a power outage, the “Previous Uptime” and “Prev. Prev. Uptime” will be restored to the last recorded values. The current Uptime cumulated time will start a new cycle.

As soon as the device is powered up, the elapsed time is counted on the top field. When your equipment is on, the time is being logged and shown as the “Uptime”: the “Power On” time show as a percentage of the elapsed time. As your equipment turns on and off, the uptime is cumulated and the percentage is updated every second. When the elapsed time reaches the “PERIOD” the device reboots. The last Uptime Percentage becomes the “Previous Uptime” and stays as a constant record show as a number and as a progress bar. On the next reboot, the Previous Uptime becomes “PREV. PREV. UPTIME” and the cycle continues.

Specifications:

Input Voltage: 8-15VDC 100mA.

Length, width, height: 2"x3.9"x4.9"(52mmx100mmx125mm)

Screen Size: 3.5 inch diagonal. (90MM)

Weight: 9 Oz. or 260 Grams.

Minimum Period Duration: 1 Min.

Maximum Period Duration: 23 Hours and 59Min. (The device can be customized for a wider range).

Update time: Once a second.

Expected Life: 100,000 Cycles (Reboots).

Warranty: 1 Year.

Please inquire at (714) 234 8170 for customization.

Other options for machine connection

This Amperage Sensor, or Current Switch will work with any of our products. It is ideal as a non-invasive solution for your machine monitoring. As the the production goes on, the current varies with each cycle. This switch will close the circuit and let our devices know when a cycle is complete. It works for Amperage from 0.5 to 50A Alternating Current but we also have a 200A version , open core. Order a 200A Amperage switch. or Order a 50A Amperage switch Adjustable.

This solution is ideal for machinery that has a cyclical movement, such as a press, or punch. The Infrared sensor has an emmiter of light and a receiver of the light that bounces back from a surface. As your press moves back and fourth, or up and down, the sensor will trigger the device and register the cycle time, or the number of parts made. This sensor works at 12V, do NOT wire it directly to the inputs. Please observe the resistors for the voltage drop down. We are glad to pre-wire it and test this with the device you are purchasing.

Uptime_Calculator_UserGuide (pdf)

DownloadContact Us

Hours

Mon | 09:00 am – 05:00 pm | |

Tue | 09:00 am – 05:00 pm | |

Wed | 09:00 am – 05:00 pm | |

Thu | 09:00 am – 05:00 pm | |

Fri | 09:00 am – 05:00 pm | |

Sat | 09:00 am – 02:00 pm | |

Sun | Closed |

Copyright © 2023 Machine Cycle Timing, Downtime Tracking and Parts Counting - All Rights Reserved.

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.